State of the

Circular Economy 2025

How We Can Grow a $5.6T Market Opportunity From 2030-2050

Something Shocking Has Occurred

The global value of the Circular Economy by 2030 has 🤯declined by 3.46X💥 in analyst reporting! As the founder of a business supporting this space, I created this report to better understand the opinion and share opportunities to accelerate progress as we look ahead to the decades between 2030–2050.

I Set out to Study This Issue In Two Phases

Economic Analysis

Opportunities for Growth

Coming soon! This will assess top industries, companies, and highlight those who are interested in sharing their story on our new Innovation Bre8k podcast.

Why did I focus on the date range between 2030–2050?

So we can focus early-stage investments on what can scale in 5+ years.

Key Data Points for Reference

Back in 2019, the World Economic Forum (WEF) estimated that by 2030, the global Circular Economy market would be worth $4.5T.

This was before the pandemic, and 5 years later this figure has been revised to $1.3T by Next Move Strategy Consulting (NMSC).

A study by Frontiers in 2024 found that “the outbreak of COVID-19 damaged sustainable economic development, causing a decrease in firm green investment.”

While circularity includes more than recycling, it is a common benchmark for material volume cycled in our economy and measure of success in waste management. It is important to recognize that some outstanding cities have achieved up to 80% waste diversion.

The Circular Economy has tripled in conversation volume, reaching megatrend status, with global policy frameworks maturing to reflect the accelerating movement.

Top 5 Findings

The circular economy market will reach $2.3 trillion by 2030—a 50% decline from the original WEF estimates, but less than the 72% decline projected by NMSC, indicating untapped opportunities.

Digital circularity solutions play a crucial role in managing asset lifetimes and enabling circular value streams and logistics. Below, I highlight the role of Artificial Intelligence (AI) and Robotics in this space.

At current growth rates, the glass and polymer recycling markets are on track to achieve zero-waste (95% recycling rate) by 2050. However, Pulp & Paper, Fabrics, Metals, and E-Waste are not on track.

With a 95% recycling success rate, the global circular economy market could reach $7.9 trillion by 2050, presenting a $5.6 trillion global growth opportunity from 2030 to 2050.

In the U.S., a 95% recycling rate could drive the market to $944.3 billion by 2050, up from $271.5 billion in 2030, representing a $672.8 billion growth opportunity in the U.S. from 2030 to 2050.

How I Framed This Economic Analysis

Before I dive into the numbers, let’s review the “Next Economy” — this is defined as an equitable, inclusive, and regenerative economy spurred by the emerging circular economy and bioeconomy markets. These markets are creating systems designed to maximize resource value with consideration for product lifecycle management. With 70% of global green house gas emissions coming from material use and handling, transitioning to these economic models is also recommended to work in better harmony with Earth’s planetary boundaries and our collective humanity.

Circular Value Stream Mapping is a tactic used to identify opportunities to:

capture value, minimize the use of new resource inputs (efficiency) and

create value, maximize the use of existing resources (transform).

Diagram Above Adapted From Plant Chicago

Value Stream

Mapping In Action

Circular Innovation Assessment for Prosthetic Parts at a National 3D Printing Manufacturer

This Study Focuses on Circularity Services and Recycling Markets

The Circular Economy focuses on product lifetime extension through digital enablers, reuse, repair, remanufacturing, and key recycling markets for pulp & paper, glass, fabrics, polymers, metals, and e-waste. This study will examine these areas. Steps like rethink, reduce, and redesign are critical for enabling downstream circularity, though harder to quantify as they depend on the skills of designers and engineers. Key enablers include emerging AI applications, life cycle assessment tools like OpenLCA, and frameworks such as Cradle to Cradle.

This Study Excludes Recovery Processes or Waste-to-Energy

Waste-to-Energy (WtE) has become an alternative to landfill waste management, but it still has negative impacts. In WtE, discarded materials are combusted to power a turbine that generates energy. Byproducts include salt, water, water vapor, and harmful elements like landfill solids, metals, fly ash, aggregate, and CO2. To support zero-waste goals, this assessment focuses on circularity tactics that enable lifetime extension. For reference, the global WtE market was valued at $39.5 billion in 2023 and is projected to grow at a 7.1% CAGR, reaching $73.3 billion by 2032.

Image originally used in the New York Times, 2018

Digital Circularity Solutions Are a Key Enabler of the Next Economy

Although we know the need for reuse, repair, remanufacture, and recycling, these markets have been slow to reach their potential. The future of the Circular Economy, I believe, depends on digital transformation. In fact, digital circularity solutions are projected to grow at an annual rate of 24.3%. The diagram above highlights opportunities for technology development that align with material and product flows.

Sourcing and procurement platforms can enable buyers to prioritize carcinogen and toxin-free function-equivalent alternatives, biomaterials, second-use, or recycled inputs, which rely on volume stability and and point-based quality data. A critical challenge for circularity is clean capture and scaling supply volumes to match demand. Clean capture involves preventing contamination in production and enabling reverse logistics or take-back systems in the sharing economy. While point-based quality testing is crucial, research is also focused on developing bulk capture models and assessing material functionality degradation due to use, contamination, and recycling processes.

Digital product passports—using QR codes, RFID, physical/chemical markers, or unique ID systems, backed by blockchain technology when granular track and trace is necessary—are increasingly used to track lifecycle activity and encourage circularity actions. These passports act as secure, permissioned information portals, enabling stakeholders to interact with materials or products efficiently, while brands can use them as touchpoints to extend the customer experience.

Network platforms and marketplaces are connecting expert service providers, gig workers, and local micro-factories to repair and remanufacture products. Given issues with IP, material composition, and recycling infrastructure, manufacturers are adopting on-site recycling and vertically integrated processes to retain their resource investment. They are also offering discounts and exchange programs to keep unique materials within their ecosystem and maintain customer loyalty.

Ownership of transportation and storage responsibilities for circular materials and products is still being debated, along with extended producer responsibility. However, flexible warehousing, recommerce, resale, and last-mile logistics services are emerging to support the dispersed movement of goods.

Spotlight on AI & Robotics

Supply chains are evolving into continuous use chains

This means that foundational data architectures and tracking KPIs are still being developed. Much of the necessary data exists in fragmented forms—on paper, product labels, PDFs (e.g., MSDS, PDS), or CAD/CAM records—so mechanisms to capture and digitize asset traits are essential.

There is both technical and physical debt, as many existing parts weren’t designed for circularity and lack traceability markers. Traditional supply chain software was built for linear 'take, make, waste' models, necessitating new platforms for continuous tracking, cycling, and workforce management. Intelligent circularity solutions may include machine vision, natural language processing (NLP), and onboarding workflows that digitize asset information through user input, such as photos or uploads. Big data initiatives are also emerging for foundational materials.

AI-based Agents Will Augment Workers and Empower Users

During product development, AI chatbots can prompt designers and engineers to follow Cradle to Cradle principles, assess 3D models, and make material or supplier recommendations based on environmental, social, and governance (ESG) priorities. AI can also assist in generating visions for circular economy futures.

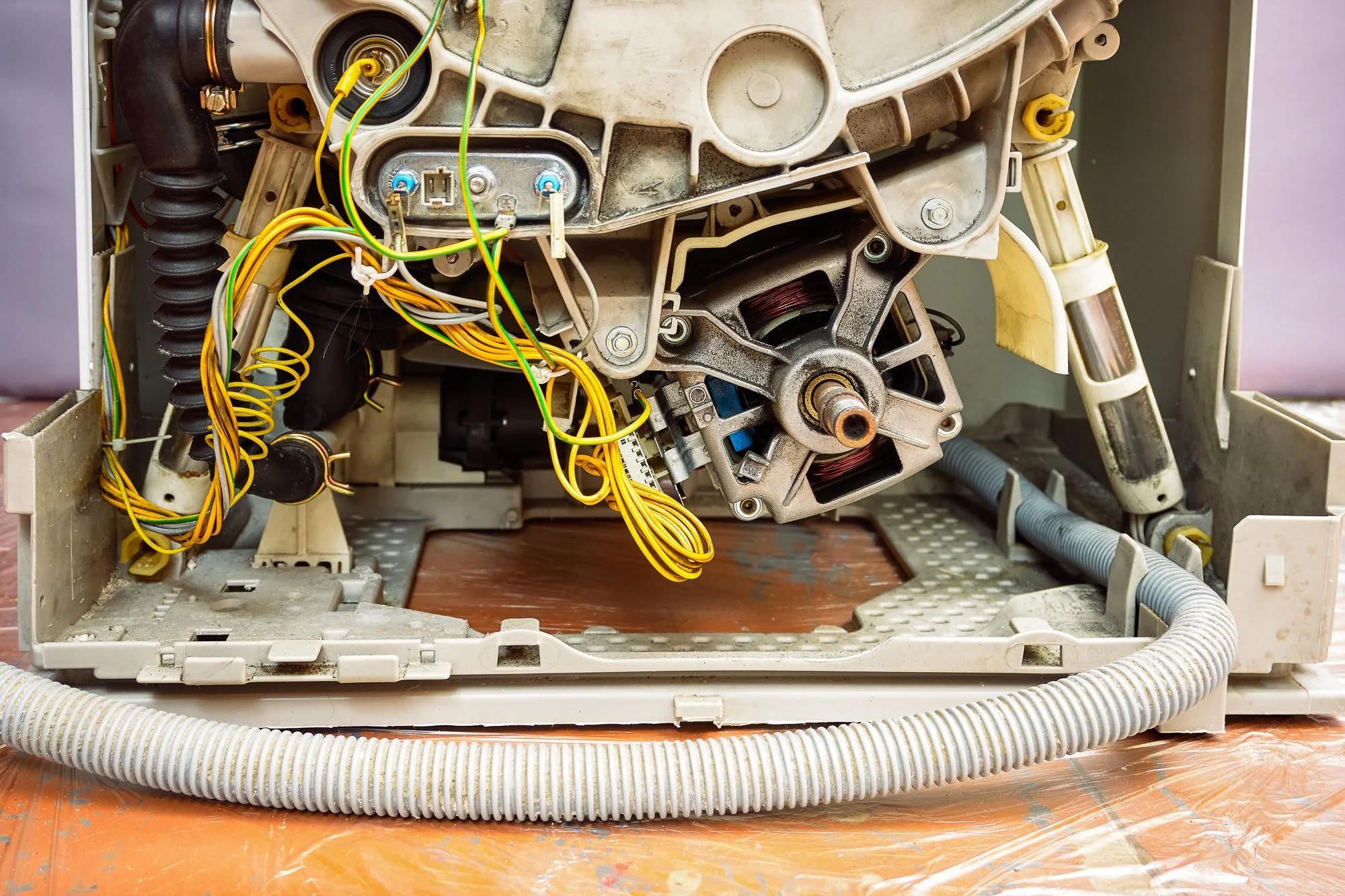

During product use, service agents can help with onboarding, safety, DIY circularity (e.g., repairs, upgrades), and logistics, while circular workforce agents manage product lifecycle tasks. These workflows can be supported by extended reality (XR), virtual reality (VR), and augmented reality (AR) for training, auditing, and quality control.

Image created using DALL-E 3 with ChatGPT

Managing Material Feedstocks

& Next-Cycle Needs

At the recycling stage, IIoT sensors detect material composition for automated sorting, while AI and robotics aid disassembly, especially for products lacking digital passports. Material feedstock fluctuations remain a challenge, leading to "mass balancing" schemes, similar to carbon offsets, to claim recycled inputs. AI can help unify data streams from non-standardized material recovery facilities (MRFs) and create flexible procurement commitments based on real-time data.

Throughout the supply and use chains, deep learning (DL) and machine learning (ML) are used to process unstructured data, accelerating digital circularity solutions. Applied analytics will predict next-cycle needs and enable personalized, real-time decision-making, including language translation. AI will also streamline communication on material and product applications.

Use Systems Thinking to Help Plan Your Go-to-Market

To ensure success, integrating Circular Economy programs with IT and OT partners for AI adoption is critical, as this can help streamline costs and drive adoption. Understanding the stakeholders affected by technology and its impact is essential. Industrial and supply chain digital transformation may lag behind other sectors, so upskilling the workforce will be key to enabling broader adoption.

Use the Systems Thinking Canvas to build resilient models that drive growth with sustainability in mind.

Research Findings

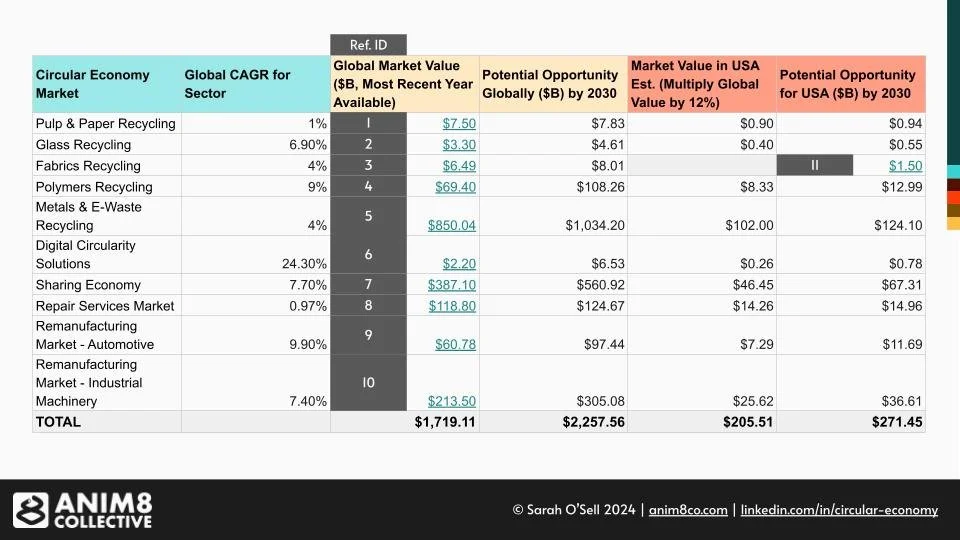

Specific market values for the United States are difficult to find, so I used global reports to conduct my assessment, along with a key statistic from the 2021 “Trash in America” report that the United States produces 12% of the global waste stream.

At the current growth rate, we are on track to achieve a 95% zero-waste recycling rate for glass and polymers ahead of 2050, but other sectors lag behind. By 2050, recycling rates are projected to reach 84% for pulp & paper, 43% for fabrics, and 91% for metals and e-waste. Innovation is needed to close these gaps.

Remanufacturing data is limited, indicating the need for further development of circular product designs and business models. For instance, future mobility solutions could feature long-life chassis with upgradeable components over time, replacing today’s model of trading in vehicles for new features.

Reference links correlated to the image Ref. ID are listed at the end of this article.

Phase 2 Preview

Opportunities for Growth

Research References

Unlock Insights

Champion the Circular Economy market with data-driven growth, sales, marketing, bespoke content & events, or easy advising.